Industrial Mixing Tips: Practical Advice, Tricks, and Hacks for Efficiency

Industrial mixing is a core process in industries such as food and beverage, pharmaceuticals, chemicals, construction, and cosmetics. It involves blending liquids, solids, or gases to achieve a uniform mixture that meets specific product standards. Without effective mixing, manufacturers risk inconsistencies, poor product performance, or even safety issues.

As industries expand, processes become more complex, and consumer demands for quality grow, the need for efficient mixing practices has become more critical than ever. This article provides insights into practical advice, tricks, and strategies that professionals can use to enhance their mixing systems and workflows.

Importance

Efficient mixing has broad implications across many sectors. It affects:

-

Product Quality – Uniform blending ensures the final product meets design and safety specifications.

-

Energy Savings – Proper mixing techniques reduce wasted energy and extend equipment life.

-

Time Efficiency – Faster, optimized mixing allows businesses to produce more in less time.

-

Worker Safety – Effective systems reduce the risk of accidents caused by equipment malfunction or improper handling of materials.

This matters not only to large-scale manufacturing plants but also to small businesses working with raw materials daily. From pharmaceuticals where dosage uniformity is crucial, to construction where cement consistency determines building strength, mixing efficiency impacts a wide variety of stakeholders.

Recent Updates

In the past year, industrial mixing has seen several developments:

-

Digital Integration (2023–2024) – Many companies are integrating IoT (Internet of Things) sensors into mixers. These sensors monitor viscosity, flow, and temperature in real time, allowing adjustments on the fly.

-

Sustainability Initiatives – There is a growing focus on reducing energy consumption. Variable frequency drives (VFDs) are now common in mixers to optimize motor efficiency.

-

Hygienic Design Standards – Especially in the food and pharmaceutical sectors, equipment manufacturers have improved clean-in-place (CIP) designs, ensuring compliance with stricter health codes.

-

Advanced Simulation Tools – Computational Fluid Dynamics (CFD) software has become a standard for predicting mixing performance before equipment purchase.

These trends highlight a shift towards smarter, greener, and safer mixing practices across industries.

Laws or Policies

Industrial mixing is affected by multiple regulations depending on the sector and country. Some relevant examples include:

-

Food Industry Regulations – In the United States, the FDA sets rules requiring sanitary design of mixers to avoid contamination. Similar guidelines exist under the European Food Safety Authority (EFSA).

-

Pharmaceutical Standards – The U.S. Pharmacopeia (USP) and Good Manufacturing Practice (GMP) standards govern equipment cleaning, validation, and batch uniformity.

-

Environmental Regulations – Agencies such as the EPA (Environmental Protection Agency) limit the release of harmful byproducts during mixing. In Europe, REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulates chemical use in industrial processes.

-

Workplace Safety – OSHA in the U.S. and corresponding agencies worldwide mandate worker training, protective equipment, and machinery safeguards for mixers.

Staying compliant is not only a legal requirement but also ensures the safety of workers, consumers, and the environment.

Tools and Resources

Professionals working with industrial mixing can leverage a variety of helpful tools:

| Tool/Resource | Purpose |

|---|---|

| CFD Simulation Software (e.g., ANSYS Fluent, COMSOL Multiphysics) | Predict mixing outcomes, test parameters virtually before scaling up |

| Mixing Power Calculators | Estimate horsepower requirements and energy efficiency |

| IoT Monitoring Platforms | Track motor load, temperature, and fluid consistency in real time |

| Industry Guidelines | FDA, GMP, and ISO standards for compliance in mixing processes |

| Mobile Apps (e.g., Engineering Toolbox, ChemEng Calculators) | Provide quick references on fluid dynamics and material properties |

Practical hacks also include regular blade maintenance, training staff on mixer operation, and using baffles or deflectors to reduce vortex formation in tanks.

FAQs

Q1: What are the most common types of industrial mixers?

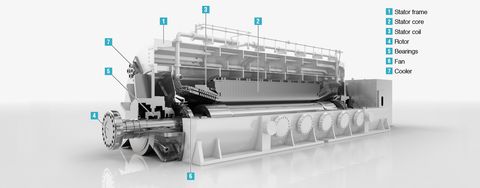

A: The most common types include agitators (used in tanks), static mixers (no moving parts), high-shear mixers (for emulsification), and ribbon blenders (for powders and solids). The choice depends on material type and process requirements.

Q2: How can I improve energy efficiency in mixing?

A: Use variable frequency drives (VFDs), select the right impeller size, avoid overfilling tanks, and perform preventive maintenance. Energy-efficient mixing reduces both operational costs and environmental impact.

Q3: What problems occur if mixing is inefficient?

A: Problems may include product separation, poor texture or consistency, uneven chemical reactions, longer processing times, and increased waste.

Q4: Are digital tools necessary for small businesses?

A: Not always. While large plants benefit from advanced IoT systems, small businesses can still improve efficiency using simple monitoring devices, regular equipment checks, and process standardization.

Q5: How often should industrial mixing equipment be maintained?

A: Maintenance schedules vary by workload and industry, but most manufacturers recommend quarterly checks for wear and tear, with annual overhauls to ensure long-term performance.

Conclusion

Industrial mixing plays a vital role across diverse industries, directly influencing product quality, efficiency, safety, and environmental impact. With recent advances in digital monitoring, simulation, and sustainable practices, companies have more opportunities than ever to optimize their operations.

By combining practical tips such as proper impeller selection, energy-efficient controls, and consistent maintenance with advanced resources like CFD tools and IoT platforms, businesses can achieve significant gains in both performance and compliance.

Ultimately, the key to successful mixing is striking the right balance between technology, regulation, and practical know-how—ensuring that processes remain efficient, safe, and adaptable in an evolving industrial landscape.