Professional Guide: Strategic Solutions & Ideas for Next-Gen Manufacturing Automation

Manufacturing automation refers to the use of technology, machines, software, and data systems to produce goods with minimal human intervention. From assembly lines to robotic arms and smart sensors, automation has transformed industries over the past century.

The concept exists because manufacturers aim to reduce costs, increase efficiency, and improve product quality. As industries face global competition and supply chain challenges, automation is no longer just about replacing manual labor—it’s about integrating advanced technologies such as artificial intelligence (AI), machine learning (ML), digital twins, and the Internet of Things (IoT).

The next generation of manufacturing automation, often called Industry 4.0, takes traditional automation further by combining data-driven intelligence with physical processes. This means factories that can adapt, predict problems, and self-optimize.

Importance

Manufacturing automation is shaping industries worldwide, affecting both large corporations and small-to-medium enterprises (SMEs). Its importance lies in solving several modern challenges:

-

Workforce gaps: Many industries face skilled labor shortages, especially in welding, machining, and assembly. Automation can fill these gaps while freeing workers for higher-value tasks.

-

Cost efficiency: Automated systems reduce waste, improve energy use, and lower operational costs.

-

Quality consistency: Machines can maintain precision and repeatability better than manual processes.

-

Global competition: To stay competitive, manufacturers must produce faster, safer, and with fewer errors.

-

Sustainability: Automation helps optimize resources and reduce emissions, aligning with environmental goals.

Who does it affect?

-

Manufacturers: From automotive to electronics, automation reshapes production methods.

-

Workers: Jobs evolve from repetitive tasks to managing and maintaining automated systems.

-

Consumers: Faster, cheaper, and higher-quality products become more accessible.

-

Governments and regulators: Must ensure safety, ethical use of AI, and workforce reskilling programs.

Recent Updates

The last year (2024–2025) has brought significant changes to next-gen manufacturing automation:

-

AI-driven predictive maintenance (2024): Companies increasingly use AI to detect machine failures before they happen, cutting downtime by up to 30%.

-

Collaborative robots (cobots): Unlike traditional industrial robots, cobots work alongside humans safely. Their adoption rose sharply in 2024, especially in small factories.

-

3D printing and additive manufacturing: Advances in metal 3D printing make it possible to manufacture complex parts on demand, reducing reliance on global supply chains.

-

Edge computing (2024): More manufacturers are processing data locally rather than in the cloud, speeding up response times for critical operations.

-

Green manufacturing: Automation is increasingly tied to sustainability. Smart energy systems and carbon-tracking tools gained traction in 2024 as companies aim to meet climate commitments.

-

Digital twins: A digital replica of a physical factory or product helps manufacturers simulate changes before applying them in real life. This technology saw rapid adoption across aerospace and automotive sectors in 2024.

Graph: Key Trends in Next-Gen Manufacturing Automation (2024–2025)

| Technology | Adoption Growth (2024–2025) |

|---|---|

| AI Predictive Maintenance | High (30% more plants adopting) |

| Collaborative Robots | Medium-High (notable in SMEs) |

| 3D Printing | Medium (expanding beyond prototyping) |

| Edge Computing | Medium (growing in large factories) |

| Digital Twins | High (especially in aerospace) |

Laws or Policies

Government policies around the world influence how automation develops:

| Region | Policy/Program | Impact |

|---|---|---|

| United States | CHIPS and Science Act (2022–2025) | Boosts investment in semiconductor and advanced manufacturing. Supports automation in electronics and supply chain resilience. |

| European Union | EU AI Act (expected 2025) | Regulates the use of AI in automation to ensure safety, transparency, and ethical practices. |

| China | Made in China 2025 initiative | Focuses on automation and robotics to achieve manufacturing independence. |

| Japan | Robot Revolution Initiative | Encourages widespread adoption of robotics and automation, especially in SMEs. |

| India | Production Linked Incentive (PLI) scheme, extended 2024 | Incentivizes investment in automated production for electronics, automotive, and renewable energy. |

Policies also emphasize workforce reskilling. For example, the U.S. Department of Labor launched new training grants in 2024 to prepare workers for jobs in automation management and AI oversight.

Tools and Resources

Manufacturers can use a wide range of resources to transition into next-gen automation.

-

Software Platforms

-

Siemens MindSphere and GE Predix: Industrial IoT platforms for monitoring and analytics.

-

PTC ThingWorx: Connects machines and data for real-time insights.

-

-

Simulation & Digital Twin Tools

-

ANSYS Twin Builder and Dassault Systèmes 3DEXPERIENCE: Enable testing and optimization before implementation.

-

-

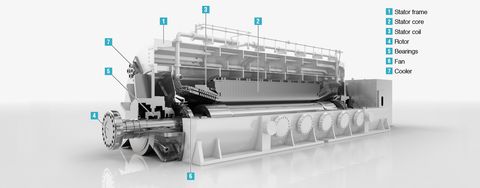

Robotics Solutions

-

Universal Robots (cobots): Easy integration into small factories.

-

Fanuc and KUKA: Widely used industrial robotics platforms.

-

-

AI & Predictive Maintenance

-

IBM Maximo and Azure IoT Suite: Tools for predictive analytics in manufacturing.

-

-

Online Resources

-

World Economic Forum – Advanced Manufacturing Hub: Reports and insights on Industry 4.0.

-

National Institute of Standards and Technology (NIST): Guides and standards for U.S. manufacturers.

-

International Federation of Robotics (IFR): Statistics and trends on global robotics use.

-

Table: Practical Automation Tools for Factories

| Category | Tool/Platform | Use Case |

|---|---|---|

| IoT & Data | Siemens MindSphere | Real-time monitoring of equipment |

| Robotics | Universal Robots | Collaborative tasks with workers |

| Simulation | ANSYS Twin Builder | Digital twin testing |

| AI Analytics | IBM Maximo | Predictive maintenance |

| Workforce | NIST guides | Training & compliance resources |

FAQs

Q1. What industries benefit most from next-gen automation?

Automotive, electronics, aerospace, and pharmaceuticals are leading adopters. However, food processing, logistics, and even textiles are rapidly integrating automation.

Q2. Will automation eliminate jobs?

Automation changes jobs rather than eliminates them entirely. While some repetitive tasks are replaced, new roles emerge in programming, maintaining, and managing automated systems. Governments and companies are investing in reskilling programs.

Q3. How does automation improve sustainability?

By optimizing energy use, reducing material waste, and enabling efficient logistics, automation supports lower carbon footprints and compliance with climate regulations.

Q4. Is automation affordable for small businesses?

Yes. While large factories deploy high-cost systems, SMEs are increasingly adopting affordable cobots, cloud-based monitoring, and modular automation solutions tailored to smaller budgets.

Q5. What are the main risks of manufacturing automation?

Risks include cybersecurity threats, system downtime due to complexity, and initial investment costs. Mitigation requires robust cybersecurity measures, redundancy planning, and careful training.

Conclusion

Next-gen manufacturing automation is more than just a technological shift—it is a transformation of how industries produce, innovate, and compete. By blending robotics, AI, IoT, and digital twin technologies, manufacturers can achieve higher efficiency, improved sustainability, and global competitiveness.

However, this transition requires careful attention to laws, workforce skills, and long-term strategic planning. By leveraging the right tools and adopting responsible automation practices, industries of all sizes can navigate the challenges and opportunities of Industry 4.0.

The future of manufacturing is not about replacing people with machines but about creating smarter, safer, and more adaptive systems where humans and technology work together.